Aluminum round tube is extensively used in various industries from automotive to architectural applications.

Aluminum tubing is widely known for its strength, flexibility, and excellent corrosion resistance. Whether it’s aluminum pipe or aluminum round tube, this kind of aluminum tubing will always be valued by lots of manufacturers because of its versatility.

Advantages of Aluminum Round Tube

Apart from being prized for its flexibility, durability, and corrosion resistance, aluminum round tube is also known for its lightweight properties. Aluminum has far superior tubing volume per weight acquired compared to steel. The combined strength and lightweight properties of aluminum serve many industries well. This is the reason it is often found in products like fuel lines, hydraulic systems, braces, and more.

The aluminum round tubes are also capable of conducting heat extremely well. Hence, it is often used for applications that depend on temperature control like solar power, air conditioning units, and refrigerators. Its excellent corrosion resistance also makes aluminum a reliable surface for paint and other similar materials compared to other metal types. This makes it very feasible for various architectural applications.

The Different Aluminum Grades

Before picking your aluminum tube, you must consider a few factors, namely the grade, temper, size and thickness. Aluminum comes in different alloys and not all aluminum alloys are suitable for heat treatment applications.

The most widely used aluminum alloys for tube includes 2024, 3003, 5052, 6061, and 7075. Due to the addition of alloying elements like zinc, magnesium, copper, silicon, and manganese, each aluminum alloy provides varying physical and mechanical characteristics. That is why it is crucial to choose the right aluminum alloy for a specific project.

Aerospace structures rely on aluminum alloys 2024, 6061, and 7075 due to their greater strength-to-weight ratios and reliable resistance against fatigue. 3003 is ideal for projects and applications that require significant corrosion resistance and durability while focusing less on ductility. 5052 meanwhile has the best weldable properties so it’s recommended for projects that require the use of several joints.

Selecting the right aluminum tube is not limited to the alloy type as well. Buyers must consider the material’s heat-treatment history. Alloys with Temper O signify the material is annealed — low in strength but high in ductility. Alloys with tempers beginning with ‘T’ like T3, T4, and T6 are heat-treated.

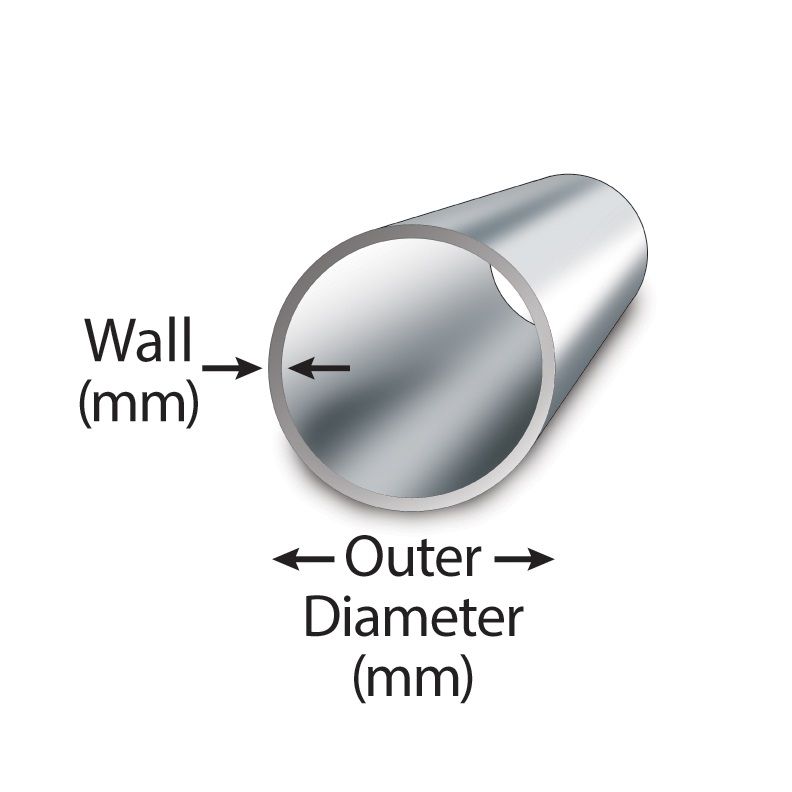

Now that you have selected an appropriate alloy and temper, the right size should be up for consideration. The aluminum round tube is available in various sizes and wall thicknesses.

Turn to Us for All Your Aluminum Round Tube Needs

Salayan Steel Wire is always glad to assist with your aluminum tubing needs. Choose a grade and size from our list and we can give you more information and help you with our cutting services.